- Vegetable oil extraction machine manufacturer

- oilmachine@doingoilmachine.com

- Phone:008613526627860

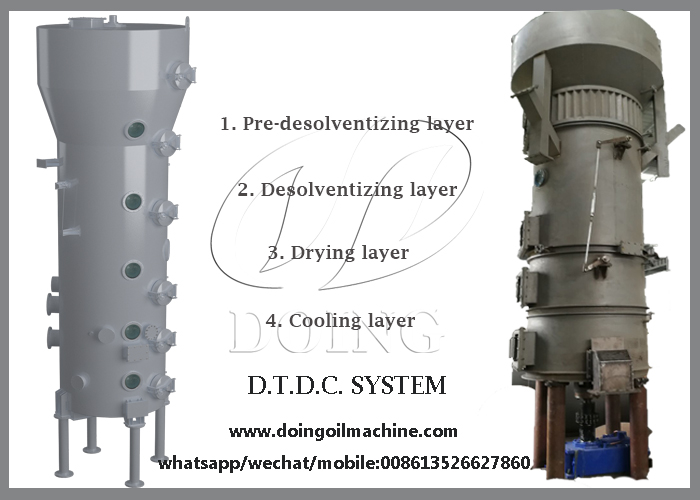

DTDC system in oil solvent extraction plant photo

D.T. D.C. system is an important part of cooking oil solvent extraction. D. T. D. C. system also called Desolventizer Toaster Drier and Cooler system in solvent extraction of vegetable oil. (Related reading: Oil solvent extraction plant)

D.T. D.C. system can be divided into the following parts:

D.T.D.C. system

D.T.D.C. system

1. Pre-desolventizing layer

In pre-desolventizing layer, heating plate helps evaporate part of solvent with plenty of heat.

2. Desolventizing layer

The shell of desolventizing layer is steam jacket, while several holes(d=2.5mm) exist on the bottom, though which inject direct steam(0.05-0.1Mpa) to heat and desolvent wet meal. Desolventizing layer is 2.3-2.5m height, while meal bed depth should be controlled in 0.8-1.8m. Because of high bed depth, steam injected though holes on the bottom can contact cake completely, which creates excellent desolventizing performance.

3. Drying layer

Drying layer is only 700mm height, which is also equipped with steam jacket on the bottom. Drying layer utilizes indirect steam(0.5Mpa) to dry wet meal.

4. Cooling layer

After the dried, the meal enters the cooling layer. The fan blows indoor air into the material layer, and the temperature of the meal drops to a safe storage temperature of 35℃-40℃.

Special design of Doing D.T. D. C. system

In order to improve production efficiency and improve meal quality, Henan Doing company specially designed dasher, gear, automatic loading device and solvent recovery system in the D.T.D.C. system.

1. Dasher

Dasher is composed of a vertical mixer shaft and 7-layers different reamer. 1 two-arm reamer lays in the bottom of redesolventizing layer and drying layer, which stir and soften meal to uniform loading meal. There are 3 layers reamer in desolventizing layer, the top one is two-armed reamer, which disperse meal from pre-desolventizing layer on the meal bed, the middle is one-armed reamer, while the bottom is two-armed reamer, which soften meal, prevent steam short circuit and enhance desolventizing performance.

2. Gearing

Gearing drives at bottom, mixer shaft links with reducer though coupler and is driven by motor.

3. Automatic loading device

Pre-desolventizing layer discharges by itself, when bed depth reaches scheduled height, discharge door open automatically.

4. Solvent recovery system

Solvent vapor comes out from top of D.T. D.C. system, and separates from wet meal by wet fines catcher and recycled after cooled by condenser.

Oil solvent extraction plant

Oil solvent extraction plant

Features of Doing D.T. D. C. system

1. Excellent desolventizing performance

2. Huge handling capacity

3. Low power consumption

4. Low steam cost

5. Easy to operate and convenient

6. Saving material

If you want to increase productivity and obtain high-quality meal, D.T. D.C. system is an important part, Henan Doing company can design the D.T. D.C. system according to the productivity and configuration of your original oil solvent extraction plant, or we can customize the oil solvent extraction production line for you. Looking forward to your contact.