- Vegetable oil extraction machine manufacturer

- oilmachine@doingoilmachine.com

- Phone:008613526627860

Vegetable oil refining machine photo

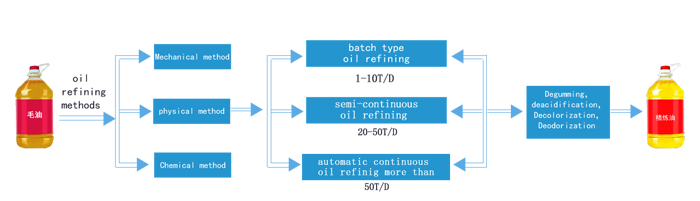

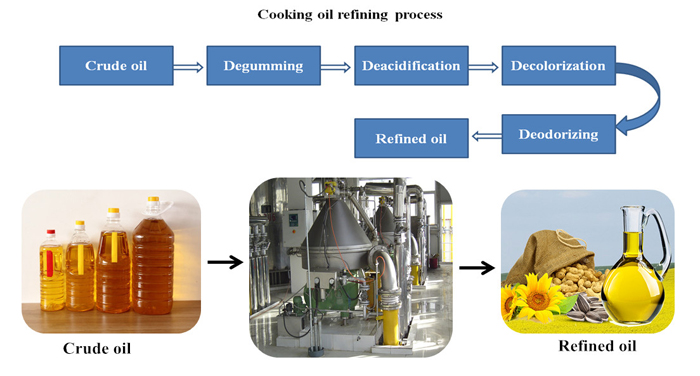

Vegetable oil refining machine is to refine the crude vegetable oil, getting rid of the deleterious impurities, then get the high quality edible oil. According to the different capacities, the vegetable oil refining machine can be devided three types: batch type, semi-continuous type and fully-continuous type vegetable oil refining machine.

Vegetable oil refining method and types of vegetable oil refining machine:

Vegetable oil refining machine types

Vegetable oil refining machine types

Different crude vegetable oil need different vegetable oil refining process. Such as peanut, soybean, sesame, castor, rapeseed etc, the refinery process has four steps: degumming, deacidification, decolorization and deodorization. For corn germ, rice bran, sunflower seed, palm oil, the refinery process has five steps: degumming, deacidification, decolorization, deodorization and dewaxing or fractionation for palm oil.

Vegetable oil refining machine related parameters:

| Steam consumption | 700KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Water (soften water) | 150Kg/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Alkali | acid valuex1-3kg/T oil |

| Circulating water cooling water yield | 150M3/ |

| Bleaching earth consumption | 3-5Kg/T oil |

| Waste bleaching earth oil content | ≤25~35% |

| Refining losses |

acid valuex1.2 (chemical refining) acid valuex 0.6 (physics refining) |

| Bleaching losses | the quantity of bleaching earth×0.25% |

| Deodorization loss consumption | ≤0.5%≤0.5% |

| Refining rate | 1-refining consumption |

1. Batch type vegetable oil refining machine:

Normally, the capacity for this type is less than 20TPD. Because the refining process of this type is refined one tank by one tank, taking a lot time and needing workers to operate.

Batch type edible oil refining machine

Batch type edible oil refining machine

2. Semi-continuous type vegetable oil refining machine:

Normally, the capacity for this type is 20-50TPD. The refinery process of this type is batch type at beginning, and the last part is continuous type.

Semi-continuous vegetable oil refining machine

Semi-continuous vegetable oil refining machine

3. Fully-continuous type vegetable oil refinery machine:

Normally the capacity for this type is above 30TPD. The refinery process of this type is fully continuous.

Fully-continuous vegetable oil refining machine

Fully-continuous vegetable oil refining machine

Detailed introduction of vegetable oil refining process:

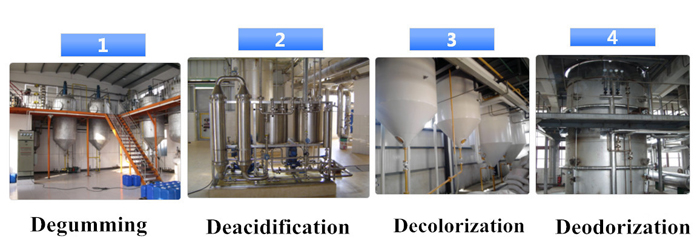

1. Degumming and deacidification

Degumming process uses phosphoric acid and water to react with crude oil, and then separate phosphatide from oil.

After enough phosphoric acid treatment, add alkali inside oil to neutralize free fatty acid, and then washing the oil several before separating the gum. This process is called deacidification.

Here the byproduct is soap stock which can be used for making soap.

Main vegetable oil refining equipment: alkali tank, oil refining tanks

2. Decolorization

Decolorization process uses white clay to bleach oil. In this step, white clay absorbs dark colorant in oil. The quantity of white clay depends on the deepness of the crude oil color. After bleaching, used clay will be filtered out by leaf filter machine.

Main vegetable oil refining equipment: decoloring tank/tower, leaf filter, pumps

3. Deodorization

This step is to remove some unnecessary odors from crude oil. Normally for chemical oil refining, it adopts plate deodorizing tower using high temperature steam to remove odors.

Main vegetable oil refining equipment: deodorizing tank, pumps

After above steps, the final product is refined vegetable oil. But some vegetable oil need more treatment such as dewaxing for sunflower oil, fractionation for palm oil etc.

Just telling us what type of vegetable oil refinery machine do you want, and Henan Doing Company will quote you in best price with advanced oil refining technology and high quality equipment. Look forward to cooperate with you!