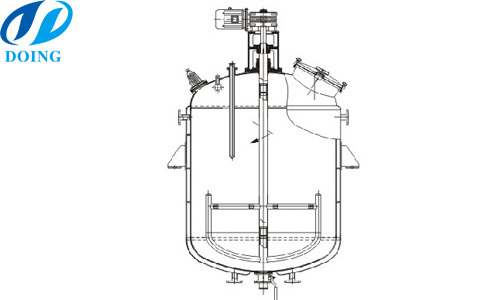

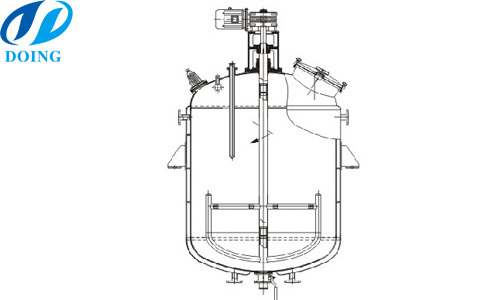

Crystallizer/crystallizing tank

Features of crystallizer/crystallizing tank we offer:

1. Stainless steel case

1. Stainless steel case

2. Anti-corrosion

3. Stable performance

4. High efficiency and energy saving

Crystallizer/crystallizing tank offers suitable crystallization condition for waxiness(or solid oil), including batch and continuous crystallizers/ crystallizing tanks.

Batch type crystallizer/crystallizing tank is similar with refining tank in structure, but it exchanges heat kacketedly with ratate speed suitable for crystallizing.

While the main part of continuous crystallizer/crystallizing tank is vertical jacketed column. Jacket connects outside cooling water, which enables heat exchange between outside cooling water and inside oils.

Dewaxing/winterization/fractionation workshop

In general, dewaxing/winterization/fractionation process needs crystallizer/crystallizing tank difinitely. However, not all oils meed dewaxing/winterization/fraction, which is to say, if oil needs dewaxing/winterization/fractionation, such as rice bran oil, palm oil, soybean oil, etc, crystallizer/crystallizing tank is difinitely needed then.

Except crystallizer/crystallizing tank, we can also offer tanks to store oil and oil seeds. We provide whole line of oil processing, including prepressing, pretreatment, solvent extraction, refining, dewaxing/winterization/fractionation.

Different oils need different process to get best oil yeild and oil quality. Our engineers can help you choose most suitable line according to your material, capacity and requirements. If you want to know more about oil processing plant. please feel free to contact us.

Dewaxing/winterization/fractionation workshop

Dewaxing/winterization/fractionation workshop

1. Stainless steel case

1. Stainless steel case