- Vegetable oil extraction machine manufacturer

- oilmachine@doingoilmachine.com

- Phone:008613526627860

Oil seeds pretreatment & pressing machines photo

Henan Glory Oils & Fats Engineering Co., Ltd has been engaged in manufacturing and exporting a huge range of oilseed pretreatment & pressing machines needed in the cooking oil processing plant, which are used for extracting oil from peanut, soybean, sunflower seed, cottonseed, sesame, palm fruit and so on.

Oilseeds our machine can process

Oilseeds our machine can process

Oil content in different oilseed:

| Peanut | 44-55% | Soybean | 18-21% | Sunflower seeds | 40-50% |

| Cottonseed | 33-40% | Rapeseed | 33-40% | Sesame seed | 45-50% |

| Rice bran | 18-20% | Corn germ | 30-40% | Flaxseed | 29-44% |

| Castor seed | 50-70% | Safflower seed | 29-45% | Camellia | 58-60% |

| Walnut | 40-65% | Palm seed | 50-55% | Coconut | 35-45% |

Oilseed pretreatment & pressing machines are necessary for big capacity cooking oil processing plant, which influences the processing working behind and the quality of crude cooking oil.

Oilseed pretreatment & pressing machines include cleaning sieve, stones removal machine, magnetic selection machine, crushing machine, softening machine, flaking machine, drying machine and so on. Because different oilseeds have different pretreatment process, it should be designed by engineers according to customers' needs.

Oilseed pretreatment & pressing machine manufactured by Henan Doing Company

Oilseed pretreatment & pressing machine manufactured by Henan Doing Company

Oilseed pretreatment & pressing machines can remove impurity, regulate moisture and temperature of the material, break oilseeds into smaller particles to change oilseed molecular structure. And it is important for the oilseeds solvent extraction process below, which influences final edible oil quality.

The following are several sections in oilseed pretreatment & pressing plant:

1.Cleaning section:

Cleaning is the beginning of oilseed pretreatment & pressing machines, which can influence the quality of the finished oil and machine service life directly. This section usually includes cleaing vibrating sieve, gravity stoner, magnetic selection, etc. All oilseeds need this step to clean raw material and remove impurities.

Cleaning section machine

Cleaning section machine

2. Husking/dehulling/shelling section:

Husking/dehulling/shelling machine is to seperate shells from nuts. Some oilseeds like peanut/groundnut, sunflower seed, cotton seed, palm kernel have hard shells above nuts, they need shelling first. If pressing with shell, the residue oil rate will be pretty high, and final oil quality will be not that good. This section is for oilseed with shell.

Different raw material need different shelling machine, the following picture is peanut/groundnut shelling machine.

Peanut shelling machine

Peanut shelling machine

3. Drying:

Drying is to reduce oilseed moisture to proper moisture. Oil seeds might be harvested in rainy season with a high moisture, so drying is essential for storage and further processing. But some oilseeds don't have to use drying machine, such as rice bran, corn germ, sesame and so on.

Flat plate dryer

Flat plate dryer

4. Crushing:

Crushing refers to crushing oilseeds into small pieces through a mechanical crushing process. For big-size or hard oilseeds, crushing reduces its size to benefit flaking, while for prepressed cake, crushing turns cake to proper size and creats better oil yeild for second press or solvent extraction. Crushing is always necessary for soybean, peanut, palm kernel, etc.

Crusher

Crusher

5. Softening:

Softening machine can adjusts moisture and temperature of oil seeds, softens and increases plasticity of oil seeds. For low oil content oil seeds (soybean, rapeseed/canola, cotton seeds, etc), softenning is an essential process for better flaking effect.

For example, oil content of soybean is 18-22%, while soybean is hard, low-moisture and low-temperature, flaking will bring plenty of powders without softenning. However, this needs to be stressed that whether softenning is needed still depends on the properties of oil seeds.

Softening pot

Softening pot

6. Flaking:

Flaking machine presses oil seeds from granulous to laminar, which brokes cell tissue of oil seeds and creats beneficial condition for cooking. Flaking also makes oil flows out smoothly when pressing or solvent extraction. Flaking roll is common for soybean.

Flaking roll

Flaking roll

7. Puffing:

Puffing turns oil seeds(cracked, flaked, or whole seed) to polyporous matters, which improves solvent permeability in extraction and increases leaching rate. Puffing is mainly for rice bran.

Puffing/Bulking machine

Puffing/Bulking machine

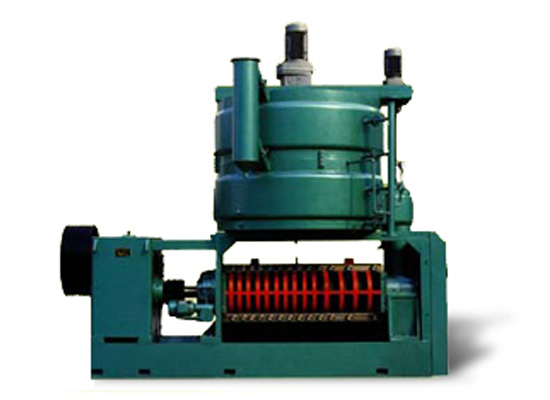

8. Cooking:

Cooking is to wet, heat, steam and to cook flakes to change the internal structure of flakes, including destorying cells, protein solidification and denaturation, etc. All these changes makes oil easy to isolate and also enhance crude oil quality. Cooking pot can be used for processing groundnut/peanut, canola seed, cottonseed, sunflower seed, etc.

Cooker

Cooker

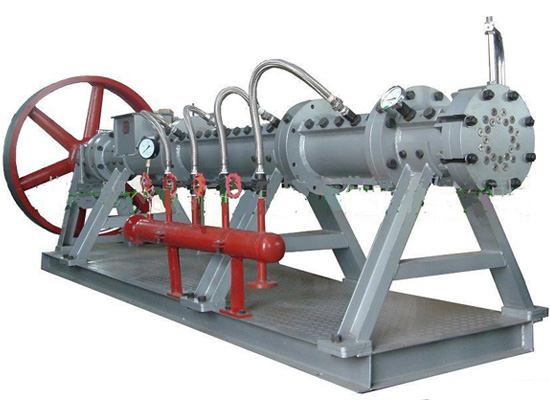

9. Pressing/prepressing:

Pressing/Prepressing is to press oil from oil seeds or cakes. In general, there are several types of oil press machines for this step. Pressing section is mainly for those oilseed processing high oil content, as groundnut/peanut,sunflower seed, canola seed, cottonseed, corn germ etc.

Cooking oil press machine

Cooking oil press machine

This is the details about oilseed pretreatment and pressing machines. Henan Glory can provide cooking oil processing plant designing, manufacturing, testing, delivery, installation, commissioning services. If you are interested in oilseed pretreatment & pressing machines or want to know more about other cooking oil proccessing plant, please leave the message in bellow table or continue reading.

Related article about cooking oil processing plant: