- Vegetable oil extraction machine manufacturer

- oilmachine@doingoilmachine.com

- Phone:008613526627860

Olive Oil Refining Machine photo

As we know, there are still some impurities such as phospholipids, FFA, pigment, odor, etc in crude olive oil. To get more cleaner edible olive oil, we need to adopt the olive oil refining machine to refine and remove these impurities, aiming at improving the olive oil storage stability, flavor and color.

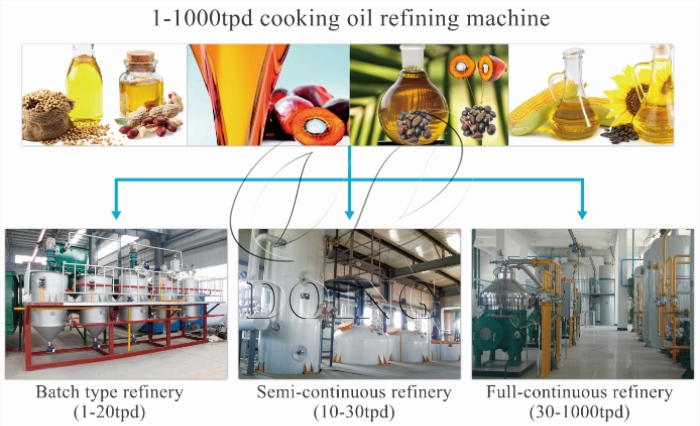

There are mainly three types of olive oil refining machine in the market, batch type refining machine, semi-continuous type refining machine and full-continuous refining machine. They have different application scopes, automation degree and prices, but they have the similar working process.

Three types of olive oil refining machine

Three types of olive oil refining machine

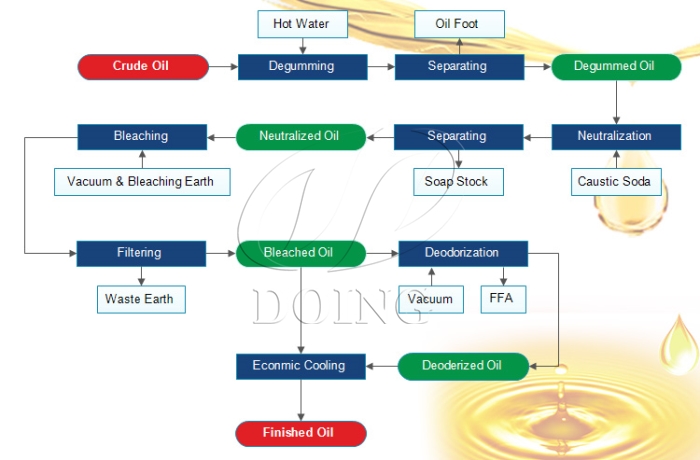

The detailed olive oil refinery process mainly includes four sections: degumming, deacidification, decoloration, deodorization.

Degumming Section:

There are usually some phospholipid, gum, and protein in the crude olive oil. But these impurity can be dissolved into water. So in degumming section, the olive oil refining machine uses the hot water to wash crude oil for two-three times to make gold phospholipid condenses and reduces colloid, and it can remove these impurity.

Deacidification Section:

In this section, some chemical materials like alkali liquor is often added for removing the acid materials. The alkali liquor will neutralize with free fatty acids and produce by-product soapstock, which can can make further process for producing soap, cosmetic, etc. After sedimentation, the soapstock will be discharged from the olive oil to complete the chemical deacidification process.

Decoloration Section:

Olive oil refining machine usually controls the temperature at about 105-110 degrees Celsius, and uses the adsorption of clay to decolorize the crude olive oil to get a clearer color of the oil. In addition to the pigments, white clay can also absorb other particulate impurities.

Deodorization Section:

The temperature required for the deodorization section is generally around 260°C. When deodorizing, direct steam is passed into the olive oil refining machine, and the difference in the volatility of oil and odor substances is used to remove odor substances in the oil, such as oxidation number, aldehydes, and ketones, etc.

Olive oil refinery process

Olive oil refinery process

If you also want to buy a set of olive oil refining machine to get high standard&high quality edible olive oil to get more benefits, welcome to contact Henan Glory Oils & Fats Engineering Co., Ltd. As a professional edible oil refining machine manufacturer,

we have professional engineers team with rich experience to customize most suitable equipment purchase scheme and olive oil refining machine for you.