- Vegetable oil extraction machine manufacturer

- oilmachine@doingoilmachine.com

- Phone:008613526627860

Batch type edible oil refinery machine photo

Batch type edible oil refinery machine is the most widely used refining production line because of its low cost and small footprint. Batch type edible oil refinery machine can remove impurities in the edible oil including phospholipids, free fatty acids (FFA) and gums, and can be used to produce 1st and 2nd grade oil from crude vegetable oil.

Batch type edible oil refinery machine

Batch type edible oil refinery machine

Batch type edible oil refinery machine process:

Degumming & Deacidification: Transfer the crude oil to a neutralization pot, heat to about 80℃, add hot water or phosphoric acid to degumming, and discharge the gum after a period of time. Add alkali to deacidify, and let out the soap stock after settling for a while.

Decolorization: After degumming and deacidification, pump the oil to the decolorization pot, add white clay after vacuum heating, and filter with a leaf filter after full reaction.

Deodorization: Deodorization can remove the odor in the oil and improve the quality of the oil. The bleached oil is heated under vacuum at high temperature for several hours, to remove all the odiferous material such as phenols, ketones, tocopherols, aldehydes etc.

After the crude oil is treated with all the above processes, we get the refined oil. This can be used for packing or as final edible oil for cooking. Doing company’s engineers can adjust the refinery process according to the types and parameters of crude oil to achieve maximum productivity.

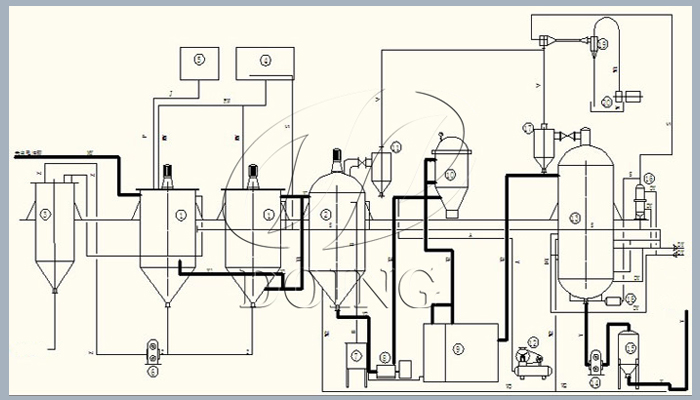

Batch type edible oil refinery process flow chart

Batch type edible oil refinery process flow chart

Features of Doing batch type edible oil refinery machine:

1. Easy to operate, less workers, low cost, small footprint.

2. Widely used: Batch type edible oil refinery machine can be used to refine various edible oil.

3. Customized capacity: Doing batch type edible oil refinery machine capacity has 1/2/3/5/10/20 ton per day you can choose.

4. The final product is of high quality and complies with national standards.

5. Doing company can customize all stainless steel batch type edible oil refinery machine, if you need.

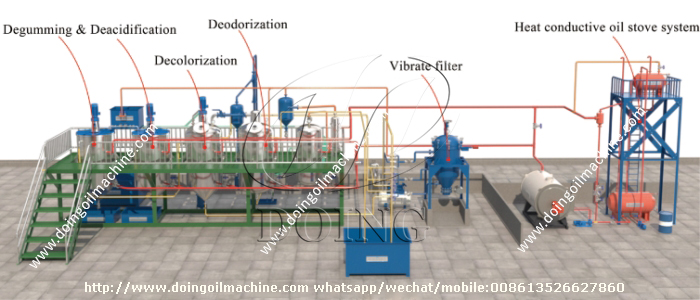

Batch type edible oil refinery machine 3D diagram

Batch type edible oil refinery machine 3D diagram

Henan Doing Company is committed to providing batch type edible oil refinery machine with the latest technology and bringing high quality products to customers. We also design semi continuous and full continuous refining production lines for medium and large refineries. If you need, please contact us.