1-30tpd batch type vegetable oil refinery plant

Different types vegetable oil refinery plant

1-30tpd batch type vegetable oil refinery plant is a process to remove unwanted and undesirable elements from the crude edible oil. The elements that are removed include the Free Fatty Acids, Phospholipids, Gums,Odour, Color, Waxes etc. 1-30tpd batch type vegetable oil refinery plant makes the vegetable oil clean and pure and improves the overall quality of the oil.

We present one of the most developed Cooking Oil Refinery Plant for processing of edible oil. There are primarily involved two types of processing- batch type vegetable oil refinery plant and continuous vegetable oil refinery plant. Through these processes, the oil is separated from impurities and other materials that can make it unfit for edible purpose.

Inorder to carry out the efficient refining process, there are basically two methods:

1) Batch Type Refinery Process

2) Continuous Type Refinery Process

From crude vegetable oil to refined edible oil machine

Henan Doing Company, is a biggest manufacturer and exporter of batch type vegetable oil refinery plants and occupies a prominent place in the China oil refinery field. All the batch type vegetable oil refinery plants designed and supplied by us have the low-operating cost and deliver the excellent refining solutions.

A batch type vegetable oil refinery plant is the most widely used system to refine different oils. This type of refining process is generally used for smaller capacity plants ranging from 1 Tons per Day to 30 Tons per Day. The batch refining system is preferred because it is low cost and quite easy to operate. This makes the batch process economical, low capital oriented and more viable for use up to 30 TPD.

The 1-30tpd batch type vegetable oil refinery process consists of different sections such as Neutralization, Bleaching, Deodorizing and Winterization.Different equipments such as neutralizer, bleacher, deodorizer, cooler, heat exchanger, vacuum equipments, plate and frame filters, pressure leaf filters, thermic fluid boiler,cooling tower, valves and pipelines etc. are used with the batch process.

Process description for the 1-30tpd batch type vegetable oil refinery plant:

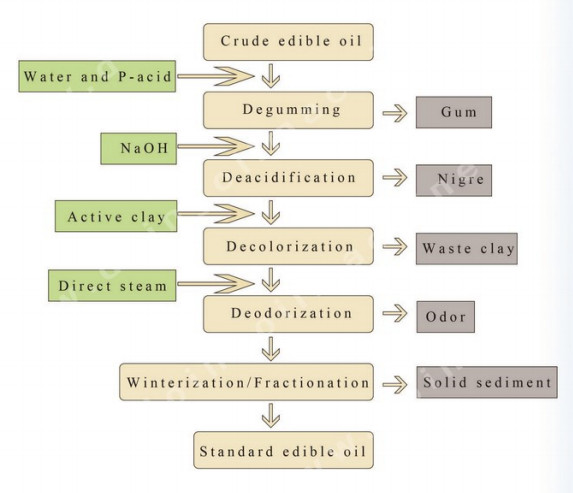

Following are the basic processes of vegetable oil refinery plant:

Vegetable oil refinery process

Neutralization Process

The crude oil is pumped to Neutralizer from oil mill or storage tank & first it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums. Neutralizer is used remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated up to about 60°C by heating coils and oil is stirred by the stirrer. The chemical reaction between free fatty acid and caustic soda forms the soap stock. This soap stock is allowed to settle down in the neutralizer from where it is collected into the soap pans. The oil is then washed with hot water to remove traces of soap particles and free alkali.

Bleaching Process

In the bleaching process of batch type vegetable oil refinery plant, excess color from the oil is removed. Neutralized oil is heated in the bleacher vessel to remove excess moisture and thereafter it is treated with a measured quantity of bleaching earth and activated carbon. Nextly oil passes through a filter to separate bleach earth and bleached oil. Oil obtained after bleaching process is light in color and has good golden type appearance.

Deodorization / Deacidification Process

The deodorization process removes odor from the oil to improve the quality and self-life of the oil.The deodorization process is important The clean bleached oil is heated in the deodorizer to remove all the odiferous material such as phenols, ketones, tocopherols, aldehydes etc. The oil is heated in the deodorizer above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised up to 200 to 220°C through thermic fluid coils. Entire process is done under high vacuum. Thus smell is removed from the oil in the deodorizer.

Cooling Process

The deodorized oil needs to be cooled at the atmospheric temperature to avoid oxidation. The deodorized oil is cooled in the cooler vessel. The water circulating coils take away the heat and the oil is cooled.

Once the process cycle is complete the oil obtained will be RBD oil which is light in color. After cooling it will pass through polishing filter to obtain sparkling light color & odorless oil for packing, which will be used as final edible oil for cooking.

De-waxing Process

Dewaxing process is carried out for Sunflower and Rice Bran Oil as they contain waxes compared to other oil. This wax is removed by the dewaxing process. The oils are subjected to winterization process. The oil is first processed in the crystallizer where it is cooled by chilled water circulation. Low temperature results in the formation of crystals which are removed in the filtration process.

Thermic Fluid Boiler, Vacuum Pump, Barometric Condenser, Catchalls, Steam Generator etc. play their role in the refining process. So these equipments are part of the batch type vegetbale oil refinery plant and connected with the vessels through pipelines.

Available capacity for 1-30tpd batch type vegetable oil refinery palnt: 1TPD, 2TPD, 3TPD , 5TPD, 10TPD, 15TPD, 20TPD and 30TPD.

Henan Doing Company can supply batch type vegetable oil refinery plants with latest technology giving pure, refined, consistent and stable finished oil at output! Get in touch with us!